Головна

EQUIPMENT FOR METALPHOTO PROCESSING

|

Markit Inc. provides the best in cutting equipment as a complement to our durable imaging technologies. These products are available as part of our full turn-key production systems packages as well as separately. All of our products are of the highest quality and durability, and Markit uses these products for all of our in-house fabrication needs. |

|

|||||||||

|

|||||||||

|

|||||||||

Metal fabricating

Shears and Corner Rounders

|

|||||||||

|

|||||||||

|

|||||||||

New Manual Cornermate Table

New Manual Cornermate Table

In response to requests for a manual table that is easier to use, a new Cornermate table has been developed that requires approximately one half of the effort of the standard table. The difference is noticeable with all materials, but it is very obvious when punching holes and slots in brass and brass plated steel.

The new table is called the CM40 Special (CM40SPCL). It has the standard adapter that permits the use of all of the original cutting units from 1/8" to 1".

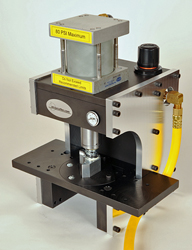

Powered Systems

Air Power (CM40AIR)

Air Power (CM40AIR)

The new air powered press is activated by a foot pedal with each stroke of the pedal producing one cycle of the press. The power is controlled by an air regulator that is built into the press. The air system also includes a filter, quick exhaust valve and a front mounted air gauge. Most work can be accomplished using only 40 PSI. It is the responsibility of the user to supply a clean, reliable air supply.

The CM40AIR works with all of the original Cornermate cutting units, including the 3/4" and 1" large format units that fit in the CM40A hand model.

The orientation of the cutting units may be changed by rotating the table adapter. In the "normal" position the cutting unit is at a 45° angle used to corner material. When rotated the cutting unit is parallel to the table for more convenient slot cutting. Also in this position, the tapped holes in the table may be used to set stops for repetitive slotting. The first and second pictures from the left below show the standard cutting unit in the two different positions. The third picture shows a large format unit in place using the special large format adapter included with the CM40AIR.

Electric Power (ECM)

Electric Power (ECM)

The ECM has a larger work surface, power-on indicator light, a stronger case and an offset post to permit the use of the slot cutting unit with material up to 5.5" wide. The cycle rate of the ECM may be adjusted using the speed control. It cycles continuously at a maximum rate of 14 strokes per minute.

The ECM works with of the original format Cornermate cutting units. These units are for corners 1/2" in size and smaller. The ECM does not work with the new large format cutting units that are for corners of 3/4" and 1".

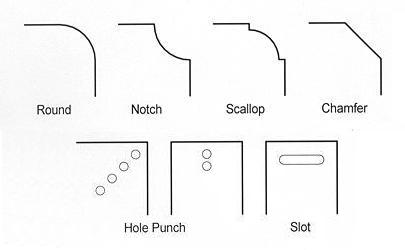

Cutting Units

Available Cutting Units:

Available Cutting Units:

Round - 1/8", 3/16", 1/4" 5/16", 3/8", 1/2", 3/4", 1"

Notch - 1/8", 3/16", 1/4", 3/8", 1/2", 3/4", 1"

Scallop - 1/4", 3/8", 1/2"

Ornamental - 3/8"

Hole Punch - 3/32", 1/8", 3/16"

Slot - 1/8" x 9/16"

Chamfer - 1/4", 3/8"

Cornermate Capacity:

Aluminum................................................. .040"

Half Hard Brass......................................... .025"

Flexible Plastic.......................................... .125"

Brass Plated Steel..................................... .015"

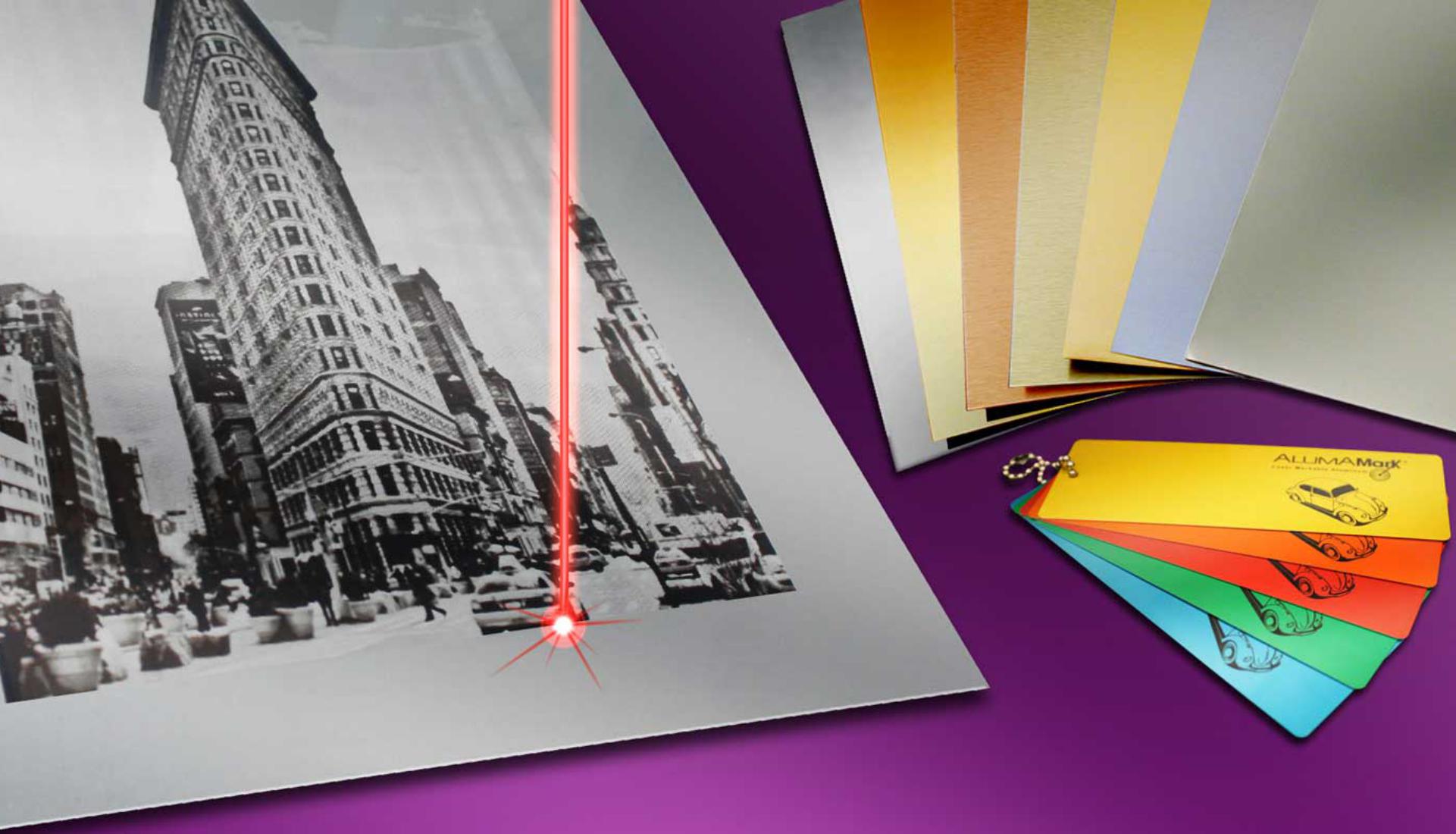

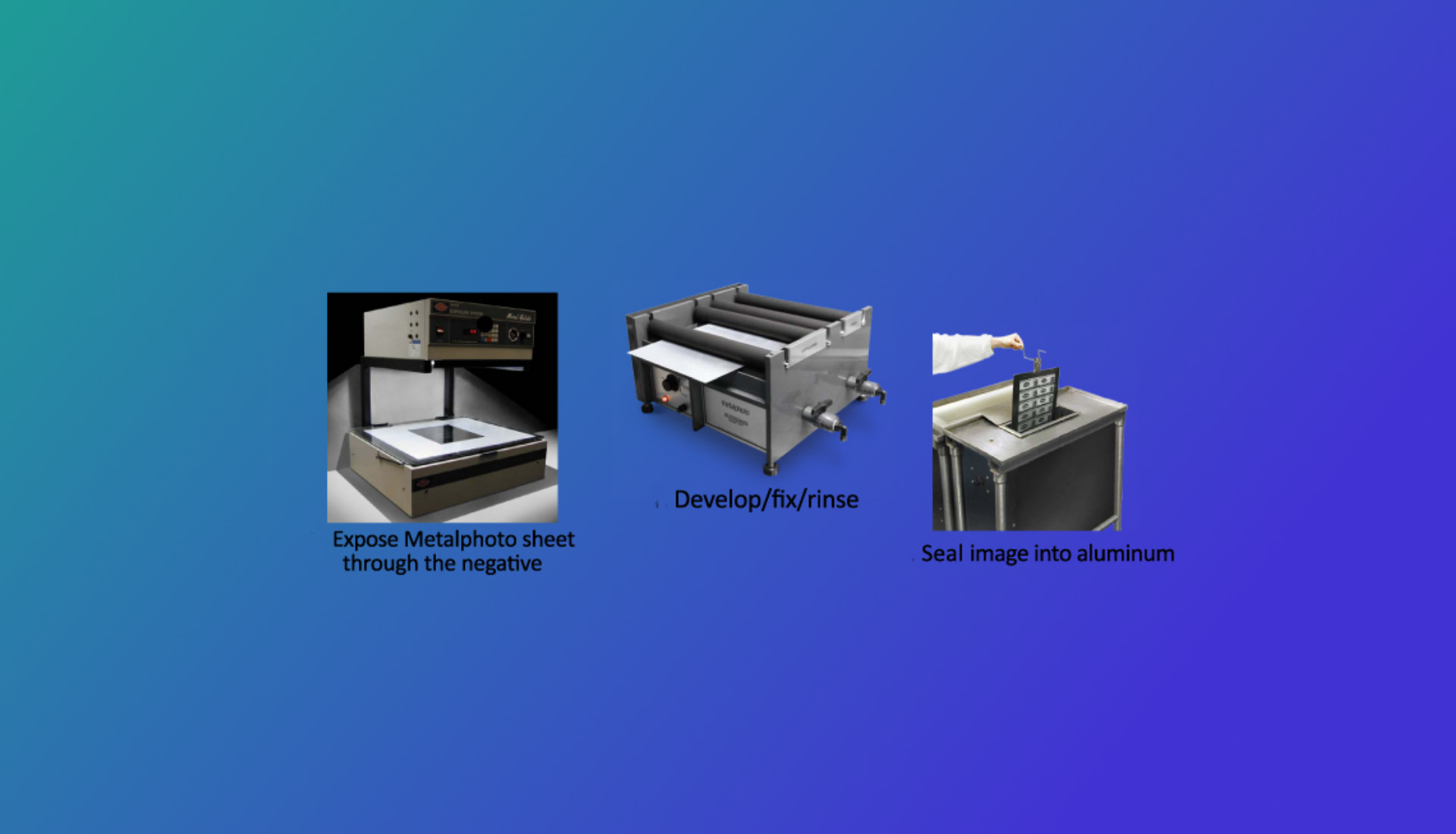

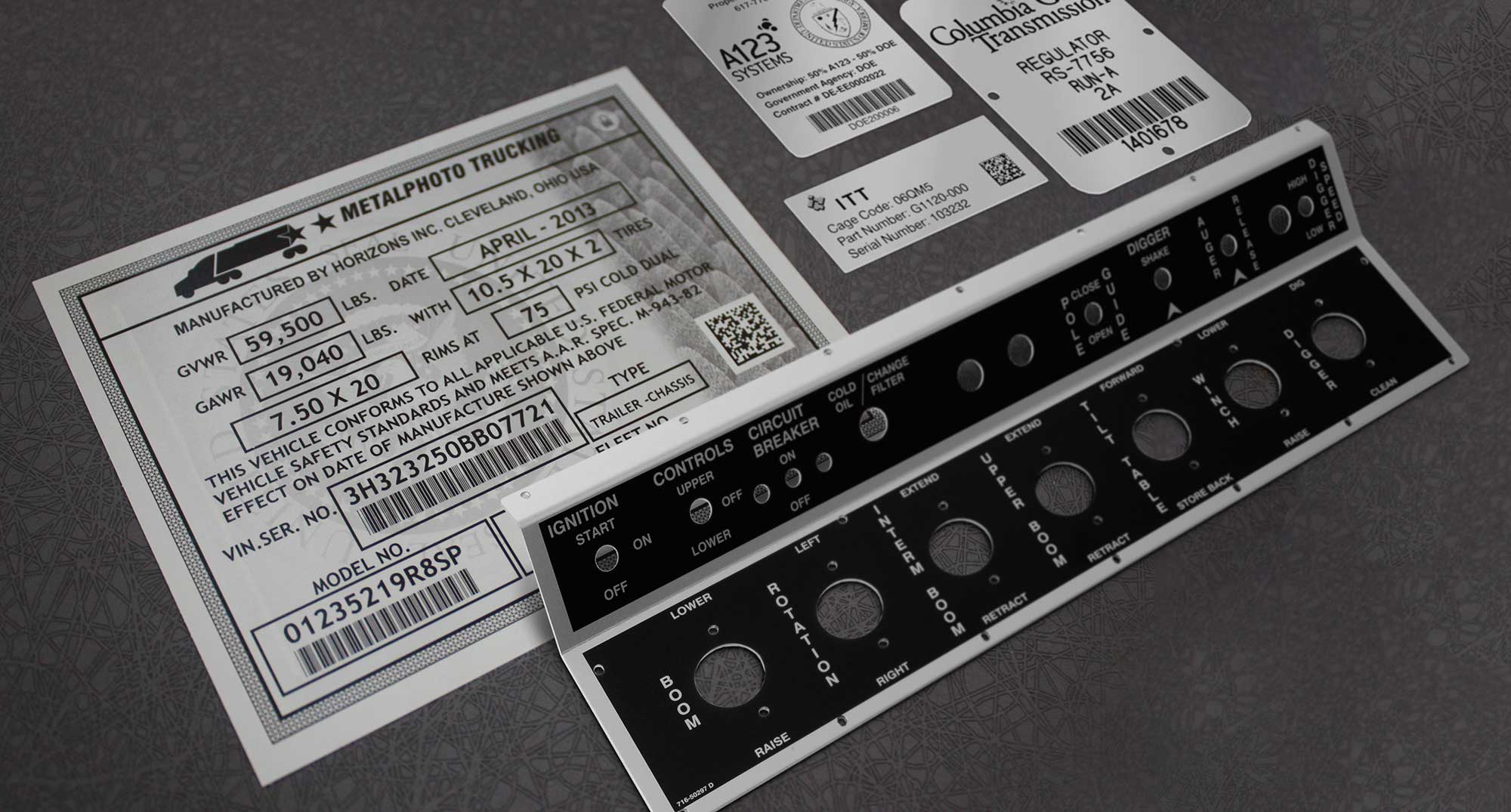

Міцність Металофото обумовлена проникненням зображення в глибину анодованого алюмінію. Корозія, сонце, абразивна дія, температура і хімічні реагенти не можуть зруйнувати таке зображення. Унікальний фотопроцес створює графіку з високою роздільною здатністю дозволяє використовувати технологію для машинозчитувальних бар-кодів, для захисту виробів від підробок і багатьох інших цілей.

Міцність Металофото обумовлена проникненням зображення в глибину анодованого алюмінію. Корозія, сонце, абразивна дія, температура і хімічні реагенти не можуть зруйнувати таке зображення. Унікальний фотопроцес створює графіку з високою роздільною здатністю дозволяє використовувати технологію для машинозчитувальних бар-кодів, для захисту виробів від підробок і багатьох інших цілей.